Industrial Mixers: Enhancing Efficiency in Nutraceutical Manufacturing

Table of Contents

- Introduction to Industrial Mixers in Nutraceuticals

- Key Benefits of Industrial Mixers

- Types of Industrial Mixers Used in Nutraceuticals

- Considerations for Selecting the Right Mixer

- Conclusion

Introduction to Industrial Mixers in Nutraceuticals

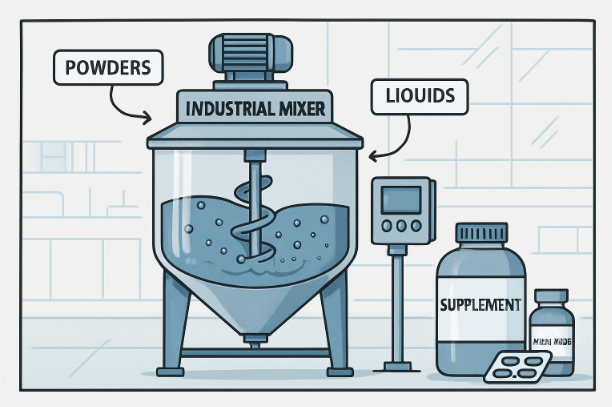

The nutraceutical industry is experiencing rapid growth due to an increased consumer focus on health and wellness. The rising demand for dietary supplements and fortified foods presents major opportunities but also poses challenges. Manufacturers must now ensure high-volume, consistent, and safe production while meeting expectations for product quality and effectiveness. A crucial technological cornerstone enabling this efficiency and reliability is the industrial mixer for nutraceuticals, which is designed to meet rigorous standards for blending, hygiene, and consistency.

When nutraceutical companies invest in the right mixing technology, they not only accelerate production cycles but also ensure every batch meets exacting quality benchmarks. Industrial mixers effectively blend ingredients into uniform mixtures, which is crucial for ensuring the labeling accuracy and potency that consumers expect from their supplements. Precision in mixing is directly tied to a product’s therapeutic efficacy, as inconsistent blending may result in under- or over-dosed servings that can harm consumer trust and brand reputation. As such, selecting the proper mixing solution is not just a process choice but an essential factor in a brand’s ability to compete and comply in today’s highly regulated market.

Key Benefits of Industrial Mixers

1. Enhanced Product Consistency

In the nutraceutical sector, homogenizing active compounds, excipients, and carriers is pivotal to creating a product that reliably delivers its claimed health benefits. Industrial mixers, such as high-shear models, excel at dispersing even the finest powders and liquids, eradicating stubborn clumps and eliminating batch-to-batch variability. Uniformity is essential not only for efficacy but also for building consumer trust in the reproducibility of each supplement dose. For manufacturers developing supplements with multiple active ingredients, this level of blending quality is especially important because it maintains ratios and consistent active content in every serving, thereby ensuring that all label claims are valid and accurate throughout the entire production run.

2. Increased Production Efficiency

Efficiency in nutraceutical manufacturing goes beyond just speed—it encompasses reduced labor, minimized downtime, and the ability to transition seamlessly between different products. Modern industrial mixers accelerate cycle times with automated controls and precision-engineered mechanisms, significantly outpacing legacy mixing approaches. Technologies like plow mixers are celebrated for their ability to achieve complete blending in significantly less time, which enables companies to scale production and launch new products faster. The time saved can be directly translated into greater throughput and improved flexibility, allowing manufacturers to remain agile in a fast-changing market while also meeting shorter lead times for clients or distribution partners.

3. Versatility in Handling Diverse Ingredients

Nutraceutical formulations feature an ever-evolving blend of vitamins, minerals, botanicals, probiotics, and specialty actives that may range from light, airy powders to dense, viscous pastes. Industrial mixers are engineered to accommodate this diversity, featuring customizable agitators and settings that can uniformly blend ingredients with contrasting properties—all while protecting the integrity of heat-sensitive and fragile components. Such flexibility positions manufacturers to innovate and respond to changing market trends efficiently. The ability to quickly adapt to new customer preferences or scientific advances, such as incorporating emerging superfoods or trending health ingredients, ensures brands remain competitive and can rapidly expand their product lines without major equipment overhauls.

4. Improved Safety and Compliance

Safety in supplement production requires both advanced engineering and strict hygiene controls. Today’s top industrial mixers are built in accordance with Good Manufacturing Practices (GMP) and FDA requirements. Features such as sanitary stainless-steel construction, easy-to-clean surfaces, and hermetic seals prevent cross-contamination, ensuring that nutraceutical operations remain compliant with global food safety standards. Cleaning processes are streamlined with rapid disassembly parts, further bolstering compliance and minimizing downtime. This focus on safety extends beyond the mixer itself; an environment that is easy to clean and disinfect also supports allergen controls and audit preparedness, which are increasingly required for customer and regulatory peace of mind.

Types of Industrial Mixers Used in Nutraceuticals

1. High-Shear Mixers

High-shear mixers are prized for their capability to produce stable emulsions and deliver exceptional dispersion of ingredients. By generating significant shear forces, they break down particles and distribute them uniformly—a critical performance factor for liquid supplements and syrups where active compounds must remain evenly suspended. This uniform distribution not only improves product texture and solubility but can also enhance bioavailability, allowing nutrients to be more easily absorbed by the body. For further technical insight, see the high-shear mixer resource on Wikipedia.

2. Tumble Blenders

Tumble blenders are optimized for gentle, yet thorough blending of powders and granules. Their tumbling motion preserves the functional and physical profile of ingredients while ensuring uniformity. As noted by Engineer Live in their article on optimising precision blending in nutraceuticals, these systems are particularly effective for formulations that involve probiotics or sensitive botanicals, where over-mixing could damage or deactivate the functional compounds. These blenders enable the safe incorporation of delicate actives, protect beneficial bacteria, and ensure product viability throughout the supply chain.

3. Plow Mixers

Plow mixers are highly versatile, capable of managing materials with a broad spectrum of particle sizes, shapes, and densities. Their robust mixing blades create intense particle movement and collisions, yielding rapid, thorough, and repeatable results. This technology is vital for nutraceutical facilities that switch between formulations quickly or rely on complex, multi-ingredient blends that require swift and dependable homogenization. Furthermore, plow mixers excel at managing cohesive or sticky materials that may pose challenges to other mixing technologies, making them suitable for granulated blends, functional food pastes, and supplement premixes.

Considerations for Selecting the Right Mixer

Every nutraceutical production setup has unique needs determined by batch size, ingredient characteristics, blending time requirements, and compliance mandates. Before investing in a mixer, manufacturers should evaluate technical specifications that align with their product portfolio, scalability targets, cleaning protocols, and the regulatory landscape. Careful selection and customization are essential to maximize throughput, ensure safety, and maintain product quality when employing novel formulation techniques. Collaborating with experienced mixing equipment providers ensures correct sizing, future-proofing, and an optimized return on investment. By leveraging industry expertise, companies can also identify integration needs, automation options, and other process enhancements that will support both short-term demand and long-term business growth.

Conclusion

Industrial mixers are indispensable to the nutraceutical sector, providing the consistency, productivity, and safety needed to compete in a dynamic, tightly regulated industry. By investing in advanced industrial mixers for nutraceutical systems and partnering with trusted equipment experts, manufacturers can efficiently deliver high-quality supplements that meet both consumer expectations and stringent compliance standards. This commitment not only enhances operational performance but also ensures public health by providing safe, trusted, and consistently effective products to individuals worldwide.

Samar

Punsuniverse — a realm crafted by me, Samar! You will find everything here that is related to puns, weather its food, animals, names or something elsse.